When you purchase through links on our site, we may earn an affiliate commission. Learn more...

Epoxy Resin VS Silicone For DIY: Which is Better?

Epoxy resin and silicone are two commonly used materials in a wide range of uses, including art, craft, and industrial manufacturing.

Both materials have distinct benefits and are adaptable, yet they have different chemical compositions, qualities, and ideal applications.

In this article, I will analyze the properties, applications, and pros and cons for either of these materials so that you can understand them a bit better and choose the one that best suits your needs.

Key Takeaways

- Epoxy Resin:

- Epoxy resin is a thermosetting polymer made of two components: the resin and the hardener.

- It must be cured to acquire its final properties, which can be initiated by heat, catalysts, or UV light.

- Epoxy resin is highly durable and can support heavy weights without breaking or cracking.

- It is transparent and can be created with a transparent finish for applications where clarity is essential.

- It can be toxic if not used properly, but once cured, it is considered non-toxic and safe.

- Common uses of epoxy resin include adhesives, coatings and sealants, electronics, jewelry and crafts, and marine applications.

- Silicone:

- Silicone is a synthetic elastomer made of silicon, carbon, hydrogen, and oxygen.

- There are various ways to cure silicone, including addition curing and condensation curing.

- Silicone is highly flexible and elastic and can be easily stretched and deformed without breaking or losing its shape.

- It is water-resistant, hydrophobic, and maintains its properties in wet and humid conditions.

- It can withstand temperatures as low as -100°C and as high as 250°C.

- Common uses of silicone include sealants, mold-making, medical applications, personal care products, cooking utensils, and automotive applications.

Properties of Epoxy Resin

Chemical Composition

Epoxy resin is a thermosetting polymer that is created by the reaction of two main components: the resin and the hardener.

The hardener is typically an amine or anhydride compound, while the resin is basically produced from epichlorohydrin and bisphenol-A.

Curing Process

This material has to be cured in order to harden and acquire its final properties. The procedure involves properly mixing the resin and the hardener and allowing them to react with each other.

Depending on the type of epoxy resin, this reaction may be initiated by heat, catalysts, or UV light. Depending on the circumstances, curing can go slowly or quickly, giving you some degree of control during the process.

Strength And Durability

It is renowned for being extraordinarily durable and long-lasting. After curing, it becomes sturdy and resistant to heat, chemicals, and impacts.

Additionally, epoxy resin can support heavy weights without breaking or cracking.

Transparency And Clarity

The transparency and clarity of epoxy resin are superb.

In situations where clarity is essential, resin can be created with a transparent finish that permits a high level of light transmission (e.g: a lamp).

Toxicity And Safety Concerns

Using epoxy resin improperly might make it toxic. The uncured resin and hardener can irritate the skin and respiratory system, and extended exposure to the fumes might have a negative impact on one’s health in the long run.

To maintain safety when using it, careful handling and protective gear are required. Once cured, however, resin is considered nontoxic and safe. Always allow it to cure in a well-ventilated area.

Properties of Silicone

Chemical Composition

Silicone is a synthetic elastomer composed of silicon, carbon, hydrogen, and oxygen. Silicones are resistant to a variety of environmental factors, including heat, cold, and UV radiation.

Its great flexibility, water resistance, and thermal stability are all attributed to its composition.

Curing Process

There are various ways to cure silicone, including addition curing and condensation curing.

Condensation curing uses a tin-based catalyst to start the reaction between two types of silicone molecules.

Addition curing uses a platinum catalyst to initiate the cross-linking of the polymer chains.

Although silicone typically takes longer to cure than other polymers, it can be accelerated by using heat or UV light.

Flexibility And Elasticity

As previously said, silicone is recognized for its remarkable flexibility and elasticity. It can be easily stretched and deformed without breaking or losing its shape.

Even if you squeeze it, it will return to its original shape without suffering any long-term damage.

Water Resistance

This material is water resistant and can maintain its properties in wet and humid conditions. It is hydrophobic, which means that it repels water and prevents water from penetrating it.

Heat Resistance

It can withstand temperatures as low as -100°C and as high as 250°C thanks to its exceptional heat resistance.

It’s also an excellent thermal insulator, which means it’ll keep other materials safe from heat damage, including your skin.

Applications

Common Uses Of Epoxy Resin

- Adhesives: Epoxy resin is often used as an adhesive. It is sometimes used in the construction industry to bond materials like wood, metal, and concrete.

- Coatings and sealants: It is also used as a coating or sealant for floors, countertops, and other surfaces. It creates a smooth, durable surface that is resistant to stains, chemicals, and wear and tear.

- Electronics: Resin is used in electronics for encapsulating and protecting electronic components from moisture, dust, and other contaminants. It is also used in the manufacture of printed circuit boards and other electronic components.

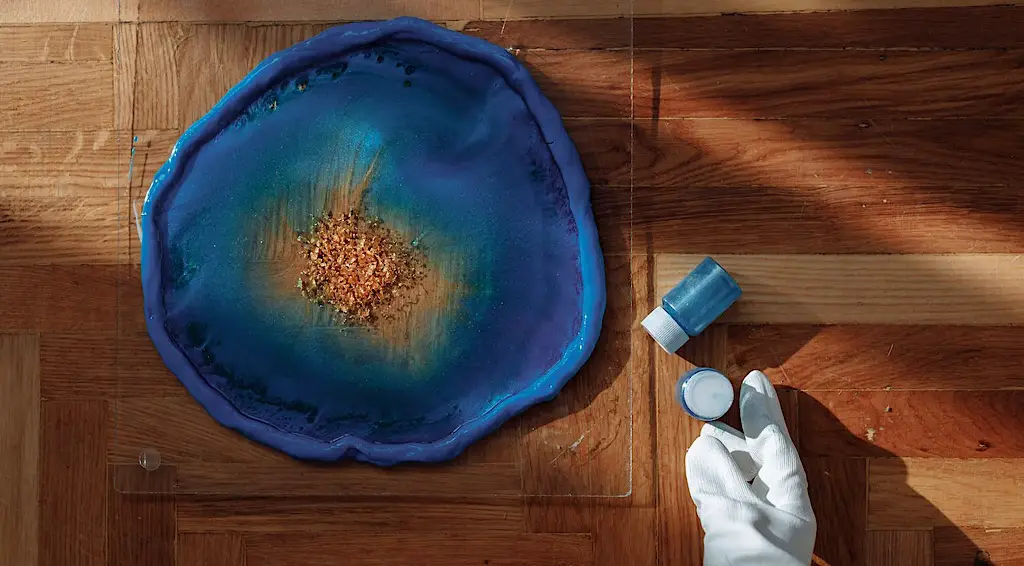

- Jewelry and crafts: One of its most popular uses is in the creation of jewelry and crafts, such as pendants, coasters, and tabletops. It can be colored and shaped to create unique designs, and it has a glossy, durable finish.

- Marine: It is often used in the marine industry for boat building and repair. It is used to bond, fill, and seal joints and surfaces, as well as to protect against water damage and corrosion.

Common Uses of Silicone

- Sealants: Silicone is commonly used as a sealant due to its water resistance and flexibility as mentioned above. It is used to seal gaps and joints in construction, automotive, marine (aquariums; non-toxic silicone type only), and sanitary applications.

- Mold-making: It is used to make molds for casting various materials, such as wax, plaster, liquid latex, and resin.

- Medical: Silicone is often met in medical applications, including implants, catheters, and medical tubing. It is biocompatible, meaning it is not harmful to living tissue and can be used safely in the body.

- Personal care products: Another common use of it is in personal care products, such as shampoos, conditioners, and skincare products, due to its ability to improve the texture and feel of the product.

- Cooking utensils: It is also used in the manufacture of cooking utensils, such as spatulas, baking sheets, cutting mats, and muffin cups.

- Automotive: It can be used in automotive applications as well, such as gaskets, seals, and hoses.

Advantages and Disadvantages

Advantages Of Using Epoxy Resin

- Resin has incredible bonding strength, which makes it ideal for adhesives and coatings. It is also highly durable and resistant to wear and tear.

- It is highly resistant to chemicals, therefore it is perfect for environments where it may be exposed to harsh chemicals, such as laboratories or industrial settings.

- Resin can be pigmented or mixed with different materials to create a unique appearance.

Disadvantages Of Using Epoxy Resin

- Epoxy resin is sensitive to UV light and can turn yellow or fade over time when exposed to sunlight.

- As I already mentioned, it emits fumes during the curing process, which can be harmful if inhaled.

- It can be expensive and time-consuming to apply, which makes it less ideal for large-scale applications but if neither of those concerns you, you can apply it on kitchen countertops and tables. However, note it will require sanding and polishing.

Advantages Of Using Silicone

- Unlike resin, silicone is highly flexible and elastic.

- It is highly resistant to water, making it ideal for moisture exposure. You can use it to seal gaps on countertops near sinks and in bathrooms. It is suggested for humid environments over wood glue which is not water-resistant at all.

- Heat resistance is another advantage of it, and it can withstand high temperatures.

You can create cheap custom molds of objects of your choice with sanitary silicone. Here’s how:

- Simply fill a bowl with water and dish soap.

- Add an amount of silicone to the water and work on it until it no longer sticks to your fingers.

- Take it out of the water and shape it into a ball.

- Gently press the object you want to create a mold on the silicone.

- Let the silicone cure. Once it does, remove the object. There you have your mold.

You can use the above method to create prosthetics for SFX makeup as well.

Disadvantages Of Using Silicone

- While silicone is an excellent sealant, its adhesion to some materials is limited; particularly plastics. In some cases, an adhesion promoter or glue may be required to ensure a strong bond. Super glue can give you a satisfying result.

- It is generally resistant to most chemicals but it can be sensitive to some solvents and oils. Exposure to these substances can cause the silicone to swell or deteriorate.

- Truth be told, it can be more expensive than other materials, such as rubber or plastic but it is WAY cheaper than epoxy resin.

- Once the silicone has cured, it can be difficult to remove, especially from porous surfaces. This can make repairs or replacements more challenging. You can remove it from gaps with the help of a sharp tool (screwer, etc).

- Even though it is highly flexible, it may not be suitable for high-stress applications where a more rigid material is required.

Final Thoughts

Silicone and epoxy resin are two common synthetic materials with distinctive features and applications.

Epoxy resin is frequently used as an adhesive, coating, and sealant as well as in the production of jewelry, electronics, and marine applications. It is renowned for its strength, durability, and transparency.

Silicone, on the other hand, is valued for its flexibility, heat resilience, and resistance to water and is frequently used in the manufacture of molds, sealants, adhesives, medical equipment, personal care items, and culinary utensils.

While each material has advantages of its own, proper handling and safety protocols must be followed to prevent any health risks.